In an event frequented by nearly 200 representatives of the Construction Industry – Airey Taylor Consulting’s work on the South Metropolitan TAFE Murdoch Campus T Block Building was celebrated as winner of the Infrastructure Projects category in the 2019 Concrete Institute of Australia (WA) Awards on Friday 5 July 2019.

Director John Taylor was lead Design Engineer on the Project and accepted the Awards (right, above) on behalf of the creative team. He was joined by Stephen Parkin (Lead Architect) and Gino Perella (Delta Corp) on the night, whose work was instrumental in the creation of the Award Winning project.

The Project

This technical college is a three-level building with mixed educational, administrative and commercial facilities created for the Western Australian Education Department.

Located adjacent to the Fiona Stanley Hospital on Jennalup Street in Murdoch, the 11,000m2 building was conceived to be similarly iconic by Architect Stephen Parkin, and to encourage engagement and learning from the students and patrons.

The development has received the 2018 Master Builders (WA)/Bankwest Excellence in Construction Awards for Best Education Building in the $20 – $50 million category. The creative use of concrete by the team plays a central part in the resulting beautiful bespoke building.

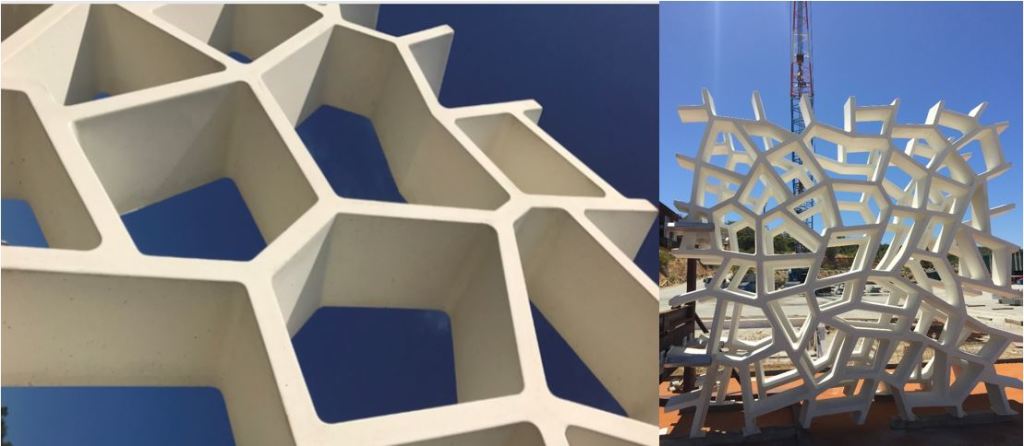

The main architectural feature of the building is unquestionably the pre-cast concrete lattice façade (above), and that has received national press coverage in the Built Office Magazine, the publication of the National Precast Concrete Association of Australia. This screen runs the length of the 120-metre-long verandah along the street frontage – offering shade, privacy and comfort to occupants along the length of the glass curtain wall, without hindering their campus view. The team overcame significant design challenges for this state-of-the-art feature.

Concrete was also used for all foundations, columns and load bearing reinforced block walls, post-tensioned concrete slabs, and additional precast panels. These precast panels are also used at each end of the building (below left and right) to provide support for the suspended slabs and to provide lateral stiffness. Design and implementation of these features are all leading edge for the Western Australian construction industry, and represent best practice of all disciplines involved.

The Materials

For the regular design aspects, commercially available concrete was used, including deployment of post-tensioned concrete that reduced the overall material required for the main slabs. Post-tensioning was used wherever possible to increase span lengths and eliminate deflections under load. 40 MPa was used for the slabs to achieve the 25 MPa strength required for stressing the slab within 3 days of pouring, and two stage stressing was employed.

The builder elected to use reinforced block walls in lieu of in situ for most walls. The blockwork cores were filled with 20 MPa, 10 mm aggregate 120 slump concrete (above centre).

When presented with the unique challenge of the development of the materials required for the lightweight, architecturally attractive lattice panel – the original concept of a fibre concrete mix was proposed by Airey Taylor Consulting. Delta Corporation’s team developed a successful mix using white cement with the addition of white oxide (right). They developed two prototype panels to ensure that manufacture was possible with the desired finishes, then manufactured the 76 irregular-shaped lattice panels for the project with a smooth Class 2 off-form finish to all surfaces.

In order to provide the requisite structural strength, Delta Corporation and Structural Engineers Airey Taylor Consulting selected a stainless steel fibre reinforcement. Installation remained challenging due to the fragility of the panels, so a bespoke steel-handling frame was created to minimise the stresses during the handling process. A few of the panel’s eccentric arms were reinforced with additional 8mm stainless steel rods to provide additional stiffness during the lifting operation.

Design and Engineering

Airey Taylor Consulting provided design and engineering of all concrete elements including foundations, columns, load bearing reinforced block walls, stairs, post-tensioned slabs, and precast panels including the unique façade. Precast panels were used at each end of the building to support suspended slabs, and provide lateral stiffness.

Lattice panels were designed with inherent spanning capacities of 3.6 metres, and built of 40MPa stainless steel fibre reinforced concrete, with ribs removed occasionally for an asymmetrical look. Arranged so they could be rotated 90 or 180 degrees, each rib matches the adjacent panel. As the lattice is see-through, background steelwork was intentionally minimised, and support installed instead at the 4 attached corners. Vertical outriggers extended from the building to attach the aligned corner panel joints.

The eastern façade was supported on precast retaining walls that also supported the first and second floor slabs. The western façade was supported by the cantilevered first-floor slab, which in turn carried loads from the second-floor slab and roof. While designed for wind and earthquake loading, weight considerations governed the design of the façade, particularly as the support brackets cast into the panels and subjected to eccentric forces.

South and east side retaining was achieved by the 150mm precast face and buttress panel fixed together and to continuous strip footings with galvanised brackets and bolts. On the eastern side 300mm thick panels were for façade support. Requirements for in situ retaining walls were removed and allowed for quicker site access for main building works.

Construction Practices

The use of post-tensioned concrete slabs provided a flat soffit and reduced formwork costs, apart from the dropped panel and edge thickening sections, which made it easier for reticulation of services. These slabs required minimum reinforcement and thus reduced slab pour intervals. Difficulties with placement of tendons in the setdown terrace areas were circumvented with careful placement and local thickening where required.

The irregular and slender trellis of the lattice panels of the main façade presented a number of challenges, particularly in terms of the formwork required for production, how to suitably reinforce the element and how to achieve a high-quality Class 2 surface finish.

Delta Corporation subsequently embarked on a concrete mix design trial leading to the development of a stainless-steel fibre reinforced, high strength, high flow concrete mix. A number of formwork trials were also conducted resulting in bespoke fibreglass moulds which were sufficiently durable enough to enable multiple casts whilst meeting the requirement for a Class 2 finish.

A prototype panel (below left) was manufactured and tested. This experiment led to the discovery of stresses induced during demoulding and handling of the units, and additional stainless-steel pins were added into selected locations on the following units. Delta Corporation designed and fabricated a specialised steel handling frame to ensure that the handling and placement of the façade occurred without incident, due to the brittleness of the prefabricated lattice.

Architecture and Environment

The brief called for a central training, amenities and administration facility on the existing Murdoch campus to consolidate older TAFE sites into one location. A strong identifiable presence was desired to complement nearby Fiona Stanley Hospital and to overlook native bushland in perpetuity (above right). Concrete was the medium selected to create function, aesthetics and user comfort.

The three-level building fronts Jennalup Street and provides a striking presence at the western campus entry. The extensive ground floor provides open and skylit covered courtyard space with colonnades and covered way links to existing campus facilities. Requirements for sunlight for the southern Horticultural training areas and the scale of existing campus buildings influenced the decision to push upper storeys to the north and maintain a single storey frontage to the south.

The ground floor has training Salons, student services, library, café, simulation office training, gymnasium and end of trip facilities with entries to the north and south. The first floor comprises general learning areas along the north and computer labs to the south along a major east/west corridor.

The second floor contains executive office space in the west and administration activities to the east, including call centres; separated by shared meeting spaces and staff amenities, including a semi-open north facing terrace.

Interior and exterior spaces were designed and furnished to maximise potential for breakout and casual meetings for students and staff. There are nooks, benches, walls, shade, ample protection from driving westerly rain, and places to take in some sun or a light breeze.

Airey Taylor Consulting would like to thank all of the relevant teams (Stephen Parkin and Armstrong Parkin Architects, Gino Perella and Delta Corp, EMCO Construction) and the Concrete Institute of Australia (WA) for the recognition of this project.

As a State Award Winner, this project enters into the National Concrete Institute of Australia Awards for consideration as a National winner.